Pipeline Welding Inspection: Ensuring Safety and Top Quality in Every Weld

Pipeline Welding Inspection: Ensuring Safety and Top Quality in Every Weld

Blog Article

Comprehensive Overview to Pipeline Welding Examination: Making Sure Integrity and Safety And Security in Pipeline Construction and Upkeep

The stability and security of pipes are critical in today's facilities landscape, emphasizing the crucial function of welding examination in pipeline building and upkeep. Pipeline Welding Inspection. The intricacies entailed in welding inspection raise essential inquiries about sector criteria and the developing innovations that might redefine these techniques.

Significance of Welding Assessment

Welding evaluation plays a crucial function in guaranteeing the integrity and safety of pipeline systems. It functions as a fundamental procedure that verifies the high quality and dependability of welded joints, which are typically the most weak spots in pipeline building and construction. Via methodical examination, examiners can determine potential issues such as cracks, porosity, and incomplete fusion, which might endanger the structural stability of the pipeline.

The relevance of welding evaluation expands beyond plain compliance with market criteria; it also safeguards public health and wellness and the environment. Comprehensive examinations can enhance the durability of pipe systems, minimizing the need for expensive fixings and downtime.

In addition to making sure security and conformity, welding evaluation promotes a society of top quality assurance within organizations. By prioritizing assessment throughout the welding procedure, companies can construct a credibility for dependability and quality, inevitably resulting in increased customer confidence and service chances (Pipeline Welding Inspection). Hence, the importance of welding evaluation can not be overstated in the context of pipeline construction and upkeep

Secret Welding Procedures

Numerous welding procedures are utilized in pipe building and construction, each with its own advantages and applications. Among one of the most extensively used approaches are Protected Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Gas Metal Arc Welding (GMAW) SMAW is favored for its flexibility and capability to execute well in various environmental conditions, making it suitable for field applications.

GTAW, usually described as Tungsten Inert Gas (TIG) welding, is identified for its capacity to produce top quality welds with excellent control over warmth input, making it ideal for thin-walled pipelines and stainless-steel products. GMAW, or Metal Inert Gas (MIG) welding, provides high deposition rates and is efficient for large jobs, usually employed in the manufacture of pipes in controlled environments.

Additionally, Submerged Arc Welding (SAW) is made use of for its deep infiltration and high productivity, particularly in the construction of large-diameter pipes. Each of these procedures adds to the overall integrity and safety and security of pipe buildings, enabling welders to pick one of the most suitable method based upon material kind, job demands, and environmental problems. Comprehending these key welding procedures is important for reliable pipe welding evaluation.

Common Issues and Their Influence

Porosity, defined by small gas pockets entraped within the weld, weakens the product and can cause leakages. Fractures, which may take place as a result of thermal stress and anxieties or inappropriate air conditioning, can result and propagate in architectural failing under stress. Undercutting, where the base steel is deteriorated along the weld grain, minimizes the efficient cross-section of the pipe, enhancing the risk of fracture.

Incomplete fusion happens when the weld metal does not correctly bond with the base steel, leading to weak areas that might stop working under tension. Slag incorporation, the entrapment of non-metallic product within the weld, can also weaken the joint's honesty. Determining and attending to these problems early in the building and construction process is important to guaranteeing the long-term dependability and safety of pipe systems, therefore guarding both the setting click here for more and the facilities.

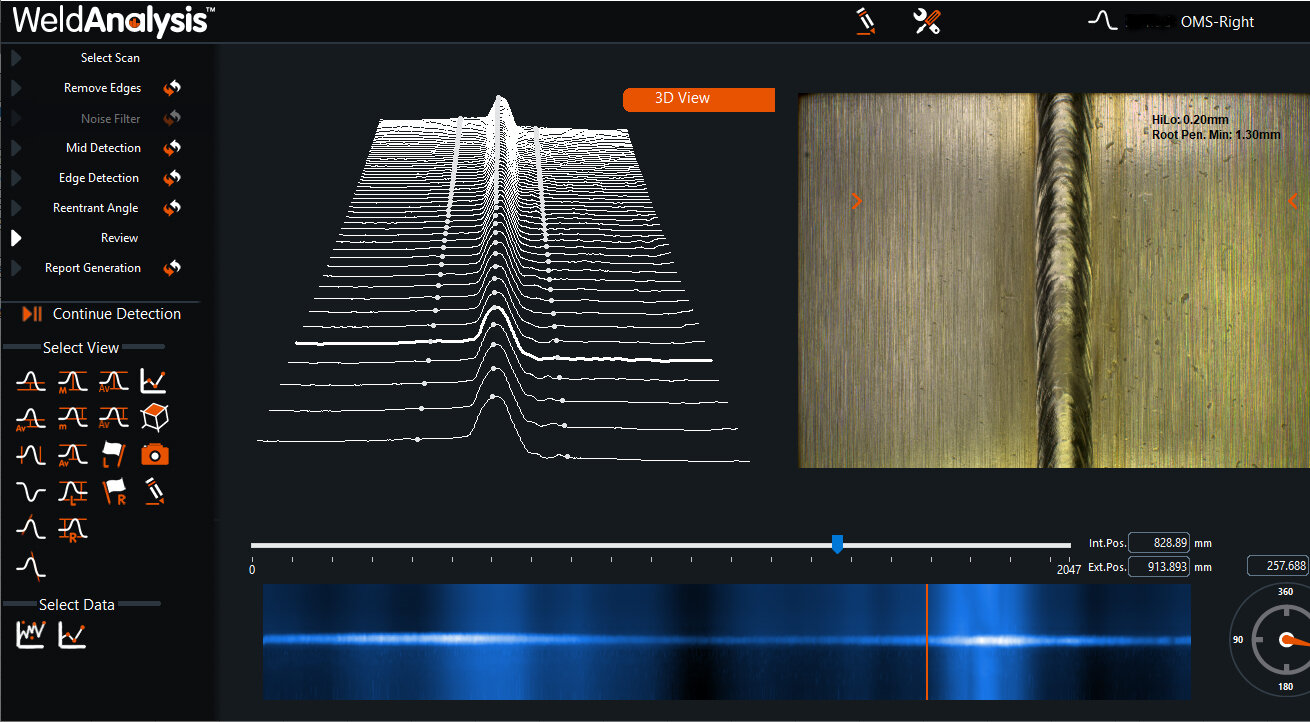

Assessment Tools and strategies

Visual examination is the initial line of defense, enabling assessors to identify surface abnormalities, imbalance, or other noticeable flaws. Ultrasonic testing utilizes high-frequency sound waves to identify inner problems, providing exact depth dimensions and characterizing issues without harming the weld. Radiographic screening uses X-rays or gamma rays to generate photos of the weld, making it possible for the recognition of internal spaces, splits, or additions.

Magnetic fragment testing is specifically efficient for discovering surface area and near-surface interruptions in ferromagnetic products. This technique entails applying an electromagnetic field and great iron particles to the weld, exposing issues via the buildup of fragments at defect sites.

In enhancement to these techniques, specialized devices such as automated ultrasonic testing devices and electronic radiography systems enhance examination accuracy and effectiveness, making certain a complete evaluation of pipeline welds during building and upkeep.

Ideal Practices for Conformity

Following best methods for compliance in pipe welding assessment is critical for making certain the integrity and security of the facilities. Organizations needs to develop a thorough quality management system that lines up with market requirements such as ASME, API, and AWS. This includes establishing comprehensive welding treatments that specify the qualifications, techniques, and materials needed for welders.

Normal training and qualification of inspection employees are important to preserve high expertise levels. Inspectors should be familiar with different non-destructive testing (NDT) methods, consisting of ultrasonic testing, radiographic testing, and aesthetic inspection, to effectively recognize possible issues.

Paperwork plays an important role in conformity; preserving accurate documents of examinations, weld procedures, and personnel credentials assists to ensure traceability and liability. Arranged audits and reviews of welding techniques ought to be conducted to recognize locations for enhancement and guarantee adherence to developed procedures.

Conclusion

In verdict, the application of rigorous welding assessment protocols is vital for guaranteeing the honesty and security of pipe construction and upkeep. Continual enhancement in examination processes will certainly contribute to the durability and integrity of pipeline systems, emphasizing the vital role of welding evaluation in the sector.

The integrity and security of pipes are paramount in today's infrastructure landscape, highlighting the essential role of welding assessment in pipeline building and construction and upkeep. Understanding these crucial welding procedures is essential for efficient pipeline welding assessment.

Sticking to best practices for compliance in pipeline welding evaluation is critical for making certain the integrity and safety of the infrastructure.In final thought, the application of extensive welding assessment methods is paramount for ensuring the honesty and safety of pipeline construction and maintenance. Constant improvement in evaluation processes will contribute to the long life and integrity of pipe systems, highlighting the essential duty of welding examination in the market.

Report this page